Getting professional results from the world of custom printing requires that one learn to work through a system. The process begins with a distinct, thoughtful design and culminates in dtf transfers, a bug-free app shortcut. Knowing each phase will bring the end result closer to your desired outcome, leaving you with a lasting impact.

Conceptualizing and Designing

Start with an idea of the visual elements you want in your project. Apply the final touches to your project using graphic design software, ensuring its high resolution and print-worthy quality. Consider colors, complexity, and scalability when making design decisions that will ultimately impact the final product’s quality.

Preparing the artwork

Now that you have your design ready, it’s time to prep the art for printing. The process involves enhancing your design to enable Kiosk printing. Make sure the resolution is 300 DPI or higher so that your final prints are sharp, clean, and clearly readable. Moreover, adjust colors appropriately for the print method to avoid any conflicts.

Select a Suitable Transfer Paper

Choosing the right transfer paper is key to getting exactly what you want. There are different types of transfer papers, such as light fabrics and dark ones, and you need to decide on the right one before your projects

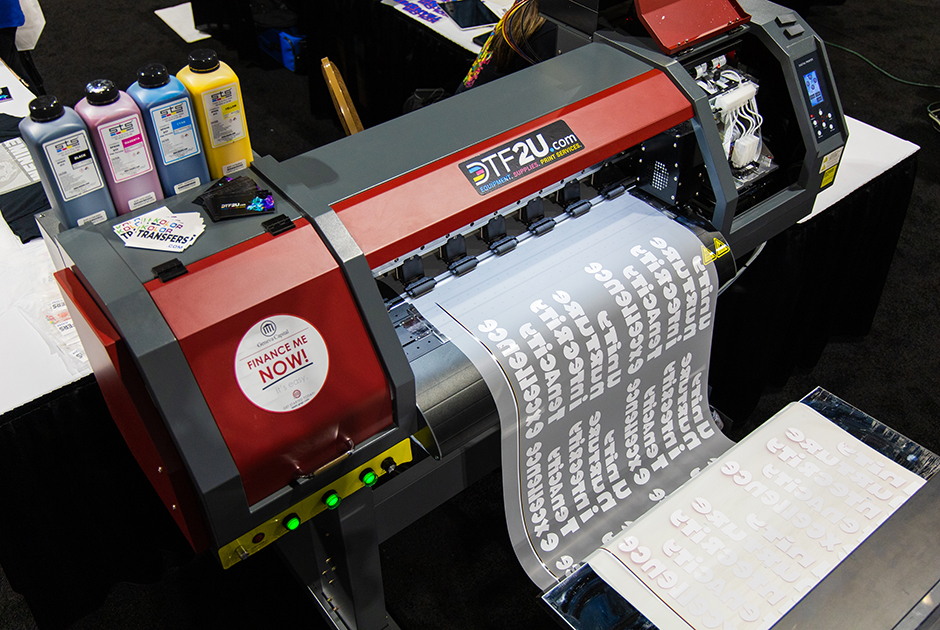

Printing the design

If you have your artwork and transfer paper, the next thing to do is print. Then save your design on the printer and print it with high-quality ink; that way, it will get the right colors. Remember to use the printer settings for your type of transfer paper. Ensure your printer is clean and your ink supply is sufficient to print the image correctly.

Applying the Transfer

A heat print machine transfers the design from paper to the final product. Set your heat press at the right temperature, and gently lay down a sheet of transfer paper on top. Follow the instructions on your transfer paper in terms of pressure none, medium, or firm and time to apply.

Those sneaky finishing touches

After completing the transfer, allow it to rest until its surface becomes too cold to handle. Upon completion, you will evaluate the transferred design and any areas that may require touch-ups. Before you peel them off, they will be smooth and completely conform to the surface.

The entire process, from designing and preparing artwork to selecting the appropriate materials and applying DTF Transfers to ensure a professional finish for your custom printing projects, can optimize every aspect of a component, thereby achieving both aesthetic appeal and long-term durability