Sheet metal fabrication operations are varied and complex. Each stage of the operation performs a specific task and also causes certain chemical and physical changes in the metal. The finished product can be iron, steel, aluminum, copper, or a combination of various metals and alloys. Skilled craftsmen perform a series of operations, resulting in a finished product that can truly be a work of art.

Each operation is carried out according to drawings prepared by engineers and draftsmen according to customer’s drawings and specifications.

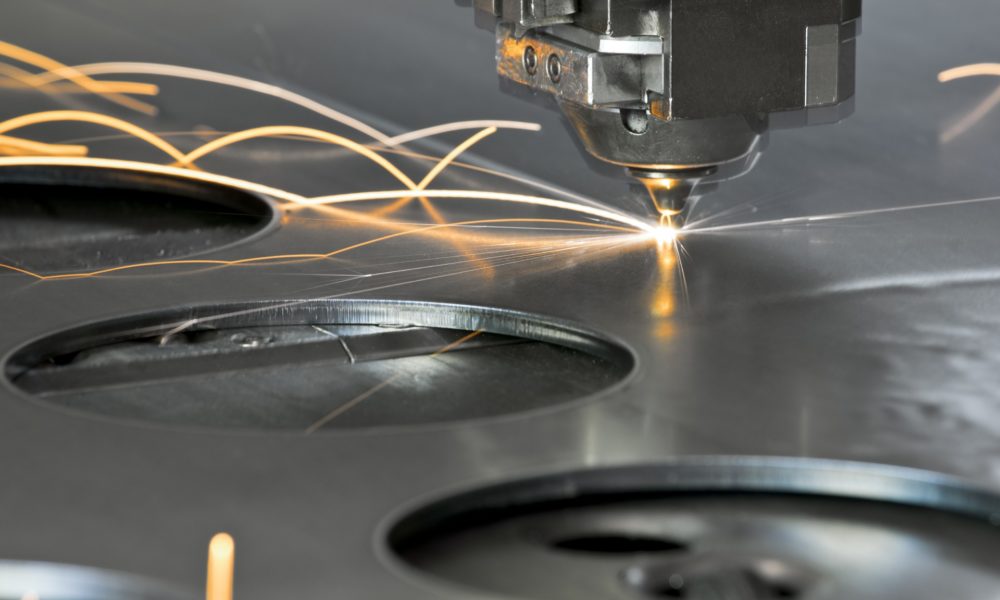

Modern equipment uses numerical control (CNC). The CNC allows the machine operator to enter the part dimensions into a computer that controls the stops and tools on the machine that the operator uses. The CNC reduces waste, prevents errors, and makes production faster and more efficient. Many modern CNC machines are designed to perform multiple operations on one machine. CNC machines can cut, drill, cut, bake, and weld most metals.

Extremely complex and detailed designs are possible using CNC. CNC burnout operations can create intricate patterns in the shape of a lace.

The manufacturing operations are basically the same and are performed in the same sequence regardless of the metal being manufactured.

These are the following operations:

Shear – Cutting metal to a specific length and width. The CNC adjusts the backgauge to a specific length for each dimension. This operation is the most time consuming of all operations and may require additional equipment, such as magnets, to allow the operator to move the part.

Punch and Cut – Use of stamps, punches, and punches to place holes of a specific size in specific locations on a flat sheet. Many CNC devices can load up to twenty-four different punches in a job setup. This allows the operator to produce more parts in less time. Some parts are so small that they must be punched out by hand with a metal punch. A stamping press is used to produce multiple dies on the same part.

Braking is the bending of a flat metal part at specific locations to shape a specific structure. The CNC equipment moves the stops to the correct size and instructs the operator to use the correct punch and punch.

Welding is the connection of metal parts to each other using electric welding with wire, rod, and other methods.

Painting: cleaning, priming and painting one piece. This includes cleaning the metal with a solvent, precoating the metal in a chemical bath that prepares the metal for painting, spraying paint on the part, and curing the part in a forced air oven.

But even with all this high tech, all metallurgical companies still require highly trained people to access the most difficult-to-reach weld spots that a computerized mechanical welder cannot access, and to form parts with double or multiple curvatures that they cannot be done without personal skill, eyes and human hand. The best sheet metal manufacturers are those who combine the best of modern technology with the most skilled metalworkers who can still work wonders with sheet metal that no machine can do today.

Sheet metal fabrication is a complex set of operations that produces a portion of everything that people use in their daily lives. Automobiles, houses, airplanes, kitchen equipment, sports cars, and toys are just a few of the products that use this manufacturing method. This business is an art form and you can create incredibly beautiful and complex designs.